Laos pipeline non-metallic compensator application scenarios in cross-sea transmission pipelines

The Gross National Product (GNP) situation in Laos is as follows:

1. **Economic Growth**:

- In 2024, the government of Laos projected that the country's Gross Domestic Product (GDP) would grow by 4.6%, surpassing the target of 4.5% approved by the National Assembly. This growth was driven by sectors such as services, transportation, and wholesale and retail trade.

- The Asian Development Bank also predicted that both the GDP of Laos for the years 2024 and 2025 would witness a growth rate of 4%.

2. **Sectoral Performance**:

- Agriculture remains a significant contributor to the economy, accounting for approximately 23.4% of the GDP. Major agricultural products include rice, coffee, sugarcane, cassava, and livestock.

- The industrial sector contributes around 29.8% to the GDP, with key industries encompassing electric power production, mining, and the manufacturing of garments, beverages, and construction materials.

- The service sector, which includes tourism, finance, and telecommunications, holds about 46.8% share of the GDP. Tourism has been notably recovering, with visitor arrivals increasing significantly after the pandemic.

3. **Challenges**:

- Despite the positive growth projections, challenges remain. Laos continues to grapple with issues such as energy shortages and high public debt levels. The government's initiatives to attract foreign investment and bolster infrastructure development are ongoing efforts to address these challenges.

In summary, while Laos is experiencing economic growth with contributions from various sectors, it faces challenges that require strategic interventions to sustain and enhance its development trajectory.

# Laotian Oil Processing Enterprises' Pipeline Construction: A Driving Force for Regional Economic Development

Laotian oil processing enterprises are playing a crucial role in the regional economy, and their pipeline construction projects serve as a significant driving force.

With the construction of pipelines by these enterprises, the transportation of oil becomes more efficient and cost-effective. It reduces the reliance on traditional transportation methods, such as road and rail, which can be time-consuming and expensive. The pipelines enable a steady and continuous supply of oil to various regions, meeting the growing energy demands of industries and households.

Moreover, the development of pipeline infrastructure attracts investment in related fields. It creates job opportunities for local people, from construction workers to skilled technicians, thus improving their living standards. This, in turn, boosts the consumption power of the local population and stimulates the growth of other industries, such as retail and services.

In addition, the stable supply of oil facilitated by pipelines supports industrial activities. Many sectors, including manufacturing and transportation, rely heavily on oil as an energy source. With a reliable oil supply, these industries can operate smoothly, leading to increased production and economic output.

Furthermore, the presence of oil processing enterprises and their pipeline construction projects enhances the overall competitiveness of the region. It makes the region more attractive to potential investors and businesses, promoting further economic development. In conclusion, the pipeline construction by Laotian oil processing enterprises is indeed a powerful driving force for the regional economy, bringing numerous benefits and opportunities for sustainable growth.

### Comparative Analysis and Prospective Outlook on Material Standards for Non-Metallic Compensators in Oil Processing Enterprises

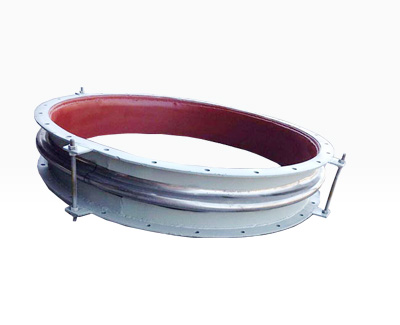

With the rapid development of the global economy and industry, the demand for energy is increasing. In the field of oil processing, pipeline systems play a crucial role in ensuring the safe and efficient transportation of oil. As an important component of pipeline systems, non-metallic compensators have unique advantages and applications in compensating for pipeline displacements caused by temperature changes, vibrations, and installation tolerances. This article aims to compare the material standards for non-metallic compensators between domestic and international oil processing enterprises and provide insights into future trends.

**1. Domestic Material Standards for Non-Metallic Compensators**

In China, with the continuous development of the chemical industry, the materials for non-metallic compensators mainly include fiberglass-reinforced plastics (FRP), rubber, and high polymer composites. FRP compensators offer excellent corrosion resistance, light weight, and good design flexibility, making them suitable for various complex environments. Rubber compensators are widely used due to their good elasticity, fatigue resistance, and low cost. High polymer composite compensators exhibit outstanding wear resistance, chemical stability, and long service life.

The "Technical Specification for Fiberglass-Reinforced Plastic Tanks and Pipelines" and other related standards regulate the technical requirements, testing methods, and quality control of FRP compensators. The "HG/T 21836-2014 Rubber Lined Ball Valves" standard specifies the technical requirements and testing methods for rubber compensators. These standards ensure that domestic non-metallic compensators meet the basic requirements of safety and reliability in industrial applications.

**2. International Material Standards for Non-Metallic Compensators**

Internationally, especially in Europe and America, the material standards for non-metallic compensators are more stringent and diverse. In addition to commonly used FRP and rubber materials, high-performance synthetic materials such as polytetrafluoroethylene (PTFE) and silicone rubber are also widely used. These materials offer excellent chemical corrosion resistance, high temperature resistance, and aging resistance, performing exceptionally well in extreme environments.

For example, in the European market, the PED directive (Pressure Equipment Directive) imposes strict regulations on the design, manufacturing, and marking of pressure equipment, including non-metallic compensators. American ASME standards also provide detailed specifications for the structural design, material selection, and testing methods of non-metallic compensators. These standards ensure that non-metallic compensators can operate safely and reliably under various working conditions.

**3. Trend Prospective**

Looking ahead, with the deepening of global environmental protection awareness and the promotion of green and low-carbon concepts, the material standards for non-metallic compensators in oil processing enterprises at home and abroad will show the following trends:

- **1. Green Environmental Protection**: The application of environmentally friendly materials will become mainstream. For example, biodegradable polymer materials and recyclable composite materials will gradually replace traditional non-metallic materials.

- **2. High Performance**: With the improvement of industrial technology levels, the performance requirements for non-metallic compensators will continue to increase. Future materials will need to have higher strength, better corrosion resistance, and longer service life.

- **3. Intelligence**: With the development of the Internet of Things and intelligence technologies, non-metallic compensators will be equipped with more intelligent monitoring and diagnostic functions. This will require materials to have better compatibility with sensors and smart components.

- **4. Internationalization**: As global trade continues to develop, the internationalization of non-metallic compensator material standards will accelerate. Domestic enterprises need to actively align with international standards to enhance their competitiveness in the global market.

In conclusion, through the comparison of domestic and international material standards for non-metallic compensators and the analysis of future trends, we believe that with technological progress and market demands, the materials for non-metallic compensators will continuously innovate and upgrade, providing safer, more reliable, and efficient solutions for the oil processing industry.

In summary, non-metallic compensators play a significant role in the pipeline construction field of petroleum processing enterprises in Laos. They can not only enhance the stability and sealing performance of the pipeline system but also reduce engineering costs and extend the service life of the pipeline. Therefore, in the process of pipeline construction, petroleum processing enterprises should fully recognize the importance of non-metallic compensators, choose suitable non-metallic compensator products, and strictly follow relevant standards for installation and maintenance to ensure the normal operation of the pipeline system. At the same time, government departments and enterprises should also increase investment in the research and development and standardization of non-metallic compensators, promote the healthy development of the non-metallic compensator industry, and provide strong support for the sustainable development of the petroleum processing enterprise industry in Laos. Stay true to our original aspirations, the future is promising! ZhongYuan wishes customers of non-metallic compensators in Laos well: thank you for the support and trust of new and old customers of non-metallic compensators in petroleum processing enterprises in Laos, and we look forward to closer cooperation and achieving more possibilities.

Gongyi City, Henan Province, China Allsites Email: 18539447368@163.com