Cambodia Chemical Enterprises Pipeline Construction Accessories of Choice Henan Nonmetallic Compensator

Cambodia has made significant progress in its industrial and economic development. Since the 1970s, the government has been dedicated to industrialization to diversify and modernize the national economy. Over the decades, Cambodia's industrial sector has grown substantially and now encompasses agriculture, manufacturing, services, and more.

The manufacturing industry is a key driver of Cambodia's industrial growth. The government encourages foreign investment in this sector, leading to the establishment of various factories and production facilities. This not only creates job opportunities but also contributes to economic growth. According to Cambodia's "Industrial Development Plan for 2015-2025," the country aims to shift from labor-intensive to technology-intensive industries, increasing the proportion of industry in GDP from 24.1% in 2013 to 30% by 2025. This plan focuses on promoting high-value-added, innovative, and competitive emerging industries such as machinery assembly, electrical equipment assembly, transportation tool assembly, and natural resource processing.

In terms of fiscal policy, Cambodia's Ministry of Finance recently released the draft "Financial Management Law for 2025," which shows that based on the assessment of the medium-term public finance framework for 2025, the industrial sector is expected to grow by 8.6% in 2025. This growth will be driven by balanced expansion in both clothing and non-clothing sub-sectors.

Moreover, Cambodia's industrial output has been growing rapidly. If it maintains an average annual growth rate of 15%, it is projected to become the sixth-largest industrial entity in ASEAN by 2030.

In conclusion, Cambodia's industrial and economic development has shown great potential and dynamism. With continued efforts and favorable policies, Cambodia is expected to achieve further growth and development in the industrial sector in the coming years.

# Exploring Cost Control Strategies for Pipeline Projects in Cambodian Chemical Enterprises

In the chemical industry of Cambodia, cost control in pipeline projects is crucial. Firstly, accurate project planning is essential. Conduct thorough research and analysis to estimate costs precisely, including materials, labor, and equipment. Secondly, procurement management matters a lot. Negotiate with suppliers to get favorable prices for quality materials. Also, consider local sourcing to reduce transportation costs. During construction, strict supervision is needed to avoid rework due to errors. Regularly monitor progress to ensure tasks are completed on time, preventing additional expenses. Moreover, training skilled workers can enhance efficiency and reduce labor costs. In summary, through meticulous planning, effective procurement, and strict construction management, Cambodian chemical enterprises can better control the costs of pipeline projects and achieve economic benefits.

# Research on Quality Inspection and Certification System of Non-metallic Compensators in Chemical Industry Enterprises' Pipelines in Cambodia

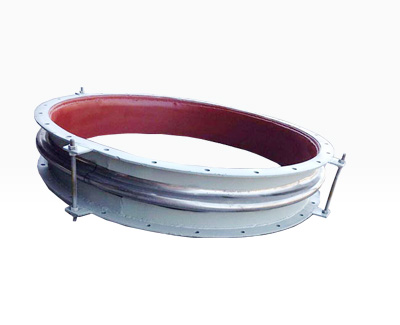

With the rapid development of Cambodia's chemical industry, the quality of non-metallic compensators in pipelines has become a key focus. These compensators play a crucial role in ensuring the safe and efficient operation of pipeline systems.

In terms of quality inspection, multiple aspects need to be considered. Firstly, material inspection is fundamental. The raw materials should meet relevant standards, with good mechanical properties and corrosion resistance. Secondly, dimensional accuracy is essential. Precision measurements are required to ensure that the compensators fit well in the pipeline system and can function as expected. Additionally, performance testing, such as pressure resistance and temperature tolerance tests, is necessary to verify their ability to withstand the actual working conditions.

For the certification system, Cambodia should establish clear and comprehensive standards. This includes referencing international advanced standards and considering the specific needs of local industries. Certification bodies should be authorized to conduct strict inspections and evaluations. Only those compensators that pass the rigorous tests can obtain the certification, which will not only guarantee the quality of products but also enhance the confidence of consumers and promote the healthy development of the chemical industry in Cambodia. In conclusion, a sound quality inspection and certification system for non-metallic compensators is of great significance for the sustainable growth of Cambodia's chemical industry.

In summary, Henan's non-metallic compensator products have played a significant role in the pipeline construction of chemical enterprises in Cambodia. This is primarily due to the efficient service and excellent quality provided by Henan's manufacturing industry of non-metallic compensators. In the future, we look forward to Henan's products playing a greater role in more fields, contributing more significantly to the economic development of our country and other regions and countries. At the same time, we also hope that Cambodian chemical enterprises can engage in deeper cooperation with Henan's non-metallic compensators, jointly promoting the development of China's chemical industry. With determination and courage, let us forge ahead!

ZhongYuan wishes customers of non-metallic compensators in Cambodia: In teamwork, let us together paint the most beautiful picture.

Gongyi City, Henan Province, China Allsites Email: 18539447368@163.com