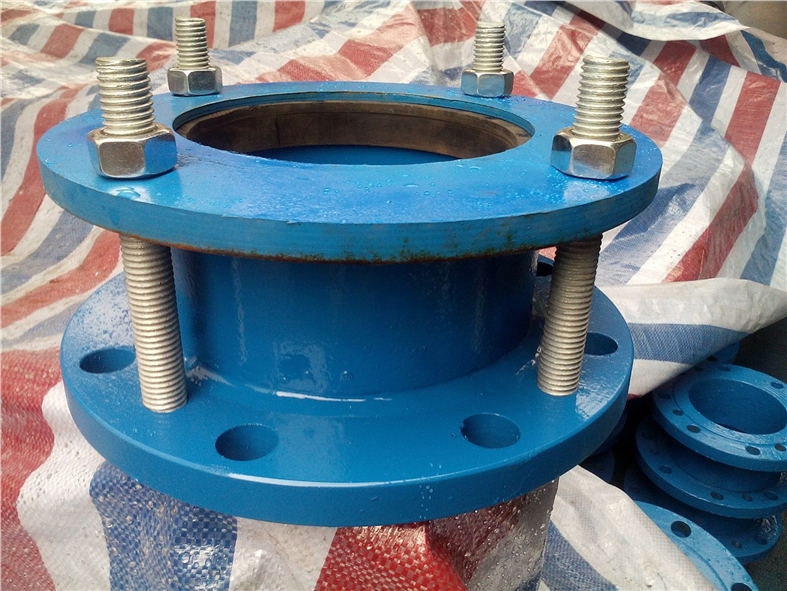

造成可曲挠橡胶接头收缩问题的因素有哪些?

Time:2019/4/25 13:46:41

造成可曲挠橡胶接头收缩问题的因素有哪些?

1.生产工艺;增加注射压力,保压压力,延长注射时间。对于流动性大的塑料,高压会产生飞边引起塌坑应适当降低料温,降低机筒前段和喷嘴温度,使进入型腔的熔料容积变化减少,容易冷固;对于高黏度塑料,应提高机筒温度,使充模容易。收缩发生在浇口区域时应延长保压时间。

提高注射速度可以较方便地使制件充满并消除大部分的收缩。薄壁制件应提高模具温度,保证料流顺畅;厚壁制件应减低模温以加速表皮的固化定型。延长制件在模内冷却停留时间,保持均匀的生产周期,增加背压,螺杆前段保留一定的缓冲垫等均有利于减少收缩现象。低精度制品应及早出模让其在空气中或热水中缓慢冷却,可以使收缩凹陷平缓又不影响使用。

2.注塑模具;多浇口模具要调整各浇口的充模速度,*对称开设浇口。可曲挠橡胶接头模具的关键部位应有效地设置冷却水道,保证模具的冷却对消除或减少收缩起着很好的效果。整个模具应不带毛刺且具有合模密封性,能承受高压、高速、低黏度熔料的充模。

3.注塑设备;供料不足,注塑机螺杆或柱塞磨损严重,注射及保压时熔料发生漏流,降低了充模压力和料量,造成熔料不足。喷嘴孔太大或太小。太小则容易堵塞进料通道,太大则将使射力小,充模发生困难。

PRE:

保养波纹管补偿器的方法

NEXT:

在使用不锈钢柔性防水套管的注意事项

Gongyi City, Henan Province, China Allsites Email: 18539447368@163.com